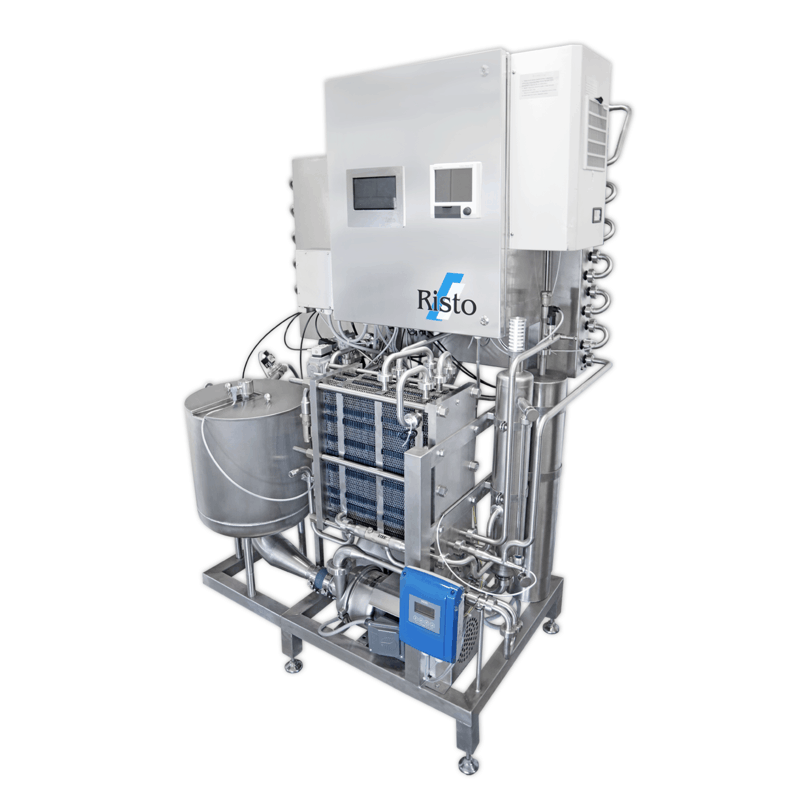

Risto Mini Pasteurizer PP-400

- Production: Up to 4800 litres per day

- Dimensions: L 120, W 80, H 180 cm

- Weight: 450 Kg

- Power supply: 12kW 400V 50Hz

- Pipe connections:

- Product inlet DN15 with butterfly valve

- Product outlet DN15

- Ice water connection DN15 (if ice water available)

- Hose connection for cold / hot water 1/2″

- Compressed air DN10, Bar 50 Nl/Min (due to safety valve)

- Gentle pasteurisation

- Energy efficient operation

- Up to 4800 litres per day

- Fast installation

- Almost fully automated

- operation

- Space-efficient design

- Adapted to farmer’s requirements

- High quality

- manufactured in Germany

- Optimised, ergonomic and simple operating process

- Very cost-effective operation

- Heat recovery

- Highly efficient and energy saving operation

- Full automatic pasteurizing and cleaning process

- Official approval by TUM Weihenstephan (performed at Risto)

- Run time: 6 hours pastorizing am Stück before forced cleaning

- Automatic detergent dosing

- Dismantable holding track for inspection by the veterinary office (required by the veterinary)

- Holding track housed (lower heat loss)

- Incl. certified line recorder and double seat release valve (Required in Germany)

- Product quantity measurement with digital display

- Constant flow rate control to ensure product quality

- Optimized, ergonomic and easy work process

- Product gentle product pump with electronic power limitation by frequency control

- Service and warranty from German manufacturer (Risto)

- Made in Germany

Risto Mini Pasteurizer PP-400

With the Risto Mini Pasteur PP-400, you can perform pasteurisation of raw milk yourself. The system is tested according to German standards and consists of two different sections. The regenerative section warms up against swing water. The heater section heats the milk up to 74°C or up to 92°C. The average holding time is approximately 30 seconds. In addition, the pasteurization device has a regenerative cooling unit against swing water, which uses and transfers the cold temperature from the cold milk to be pasteurized. If required by the client, the Risto Mini Pasteur PP-400 can be equipped with a cooling section around ice water. Nominal diameters of the product input and output, as well as ice water supply port, are 15mm. Optionally, you can also connect the device to cold or hot water and compressed-air supply via a 10mm port. The easy-to-use Risto Mini Pasteur PP-400 ensures gentle pasteurization of your milk with simple operation and at low operating costs.

| Product | Price in Euro | |

| Pasteurizer PP-400 | 29.990,- | |

| Cleaner Niroklar and neomoscan 24 kg canister | Included | |

| Cleaner Niroklar and neomoscan 24 kg canister | Included | |

| Raw milk pump unit | 4.990,- | |

| Phone Service Hotline | Included |

All prices excl. VAT

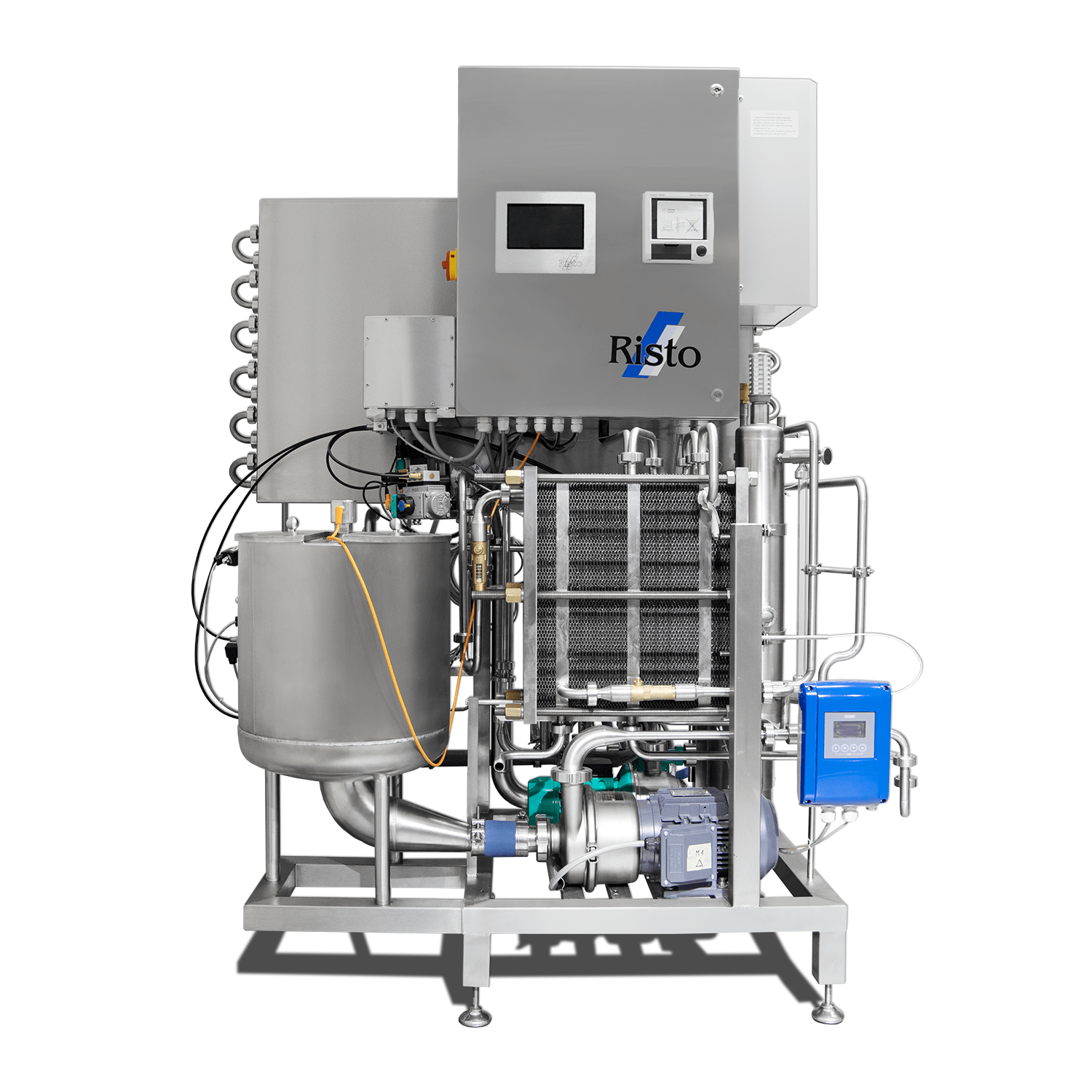

Risto milk pasteur PP-600 / 1000

- Production: 600 up to 1.000 liters per hour

- Dimensions: Length 2400, Width 900, Height 2200 MM

- Weight: 650 Kg – 750 Kg

- Pipe connections: Product inlet DN25 with butterfly valve, product outlet DN25,

- Ice water connection DN 25,

- Cold / hot water connection DN 25

- Compressed air 1/2 ” 8 bar 125 Nl/Min

- Production: 600 up to 1.000 liters per hour

- Gentle pasteurisation

- Energy efficient operation

- Fast installation

- Almost fully automated

- operation

- Space-efficient design,

- Adapted to farmer’s

- requirements

- High quality,

- manufactured in Germany

- Optimised, ergonomic and simple operating process

- Very cost-effective operation

- Heat recovery

- Highly efficient and energy saving operation

- Full automatic pasteurizing and cleaning process

- Official approval by TUM Weihenstephan (performed at Risto)

- Run time: 6 hours pastorizing am Stück before forced cleaning

- Automatic detergent dosing

- Dismantable holding track for inspection by the veterinary office (required by the veterinary)

- Holding track housed (lower heat loss)

- Incl. certified line recorder and double seat release valve (Required in Germany)

- Product quantity measurement with digital display

- Constant flow rate control to ensure product quality

- Optimized, ergonomic and easy work process

- Product gentle product pump with electronic power limitation by frequency control

- Service and warranty from German manufacturer (Risto)

- Made in Germany

Risto milk pasteurizer PP-600 / 1000

With the Risto Milk Pasteurizer PP-600 / 1000, you can pasteurize your milk yourself. For simple and cost-effective heat treatment of the raw milk, the device is equipped with a value-added technology. The latter includes a hot water pump made of stainless steel, as well as a plate heat exchanger and an electric kettle. In addition, the convenient short-term heater contains an integrated forerun vessel. The milk pasteurizer electronics include, among other things, a switching device and a temperature recorder, for reliable documentation of all measured values. The device is regulated and controlled via software. The technology also includes an inductive milk quantity recording. Furthermore, the Risto Milk Pasteurizer PP-600 / 1000 is equipped with a digital temperature regulator. Milk delivery through the plate unit and milk removal from the balance tank is carried out by stainless steel pumps. For effectively keeping a hot temperature, the system is also equipped with a regenerative section, a heating section, a pipe heater, a regenerative cooling and an after-cooling section. Depending on the device type, you can pasteurize from 600 to 1,000 litres of milk per hour.

| Product | Price in Euro | |

| Pasteurizer PP-600 | 39.990,- | |

| Pasteurizer PP-1000 | 43.990,- | |

| Cleaner Niroklar and Neomoscan 24kg canister | Included | |

| Raw milk pump unit | 4.990,- | |

| Phone Service Hotline | Included |

All prices excl. VAT

Batch cleaning

- Length: 1250mm

- Width: 900mm

- Height: 1900mm

- 2 x 7.5 kW electric heating unit

Stainless steel batch cleaning with gravitational flow to the pasteurizer, manual control,consisting of 2 containers, isolated lye and acid tanks with 2 x 7.5 kW electric heating units and a thermostat, various valves and a concentration indicator as well as connecting pipes from the batch cleaning unit to the pasteurizer.

Cleaning with circulating detergent

For small and mid-sized agricultural enterprises cost-saving and hygienic working is very important. Both of these goals can be achieved by the Risto cleaning system with circulating cleaning agents. The individual components are made of easy-to-clean and durable stainless steel. In two containers, alkali and acid are reliably isolated from each other.

The principle is that the cleaning agents are re-used many times (circulation cleaning). That means, the cleaning agent does not drain but is collected during cleaning. As a result, this collected agent is available for the next cleaning. Equipment features include an electrical 7.5KW heater with integrated thermostat, various valves, as well as an indicator showing concentrations of individual cleaners. Connection pipes convey the cleaning liquids from the Risto batch cleaning to the next pasteurizer. The price of this cleaning technology is generally favourable. Thus, even small farms and milk producers with small budgets can gain from this innovation in the longer term, since the consequent costs of the water consumption can be reduced thanks to the possible use of rinsing water – even in case of small production amounts.

Deutsch

Deutsch Français

Français Español

Español Русский

Русский